How to Choose the Right Paper Slitting Machine

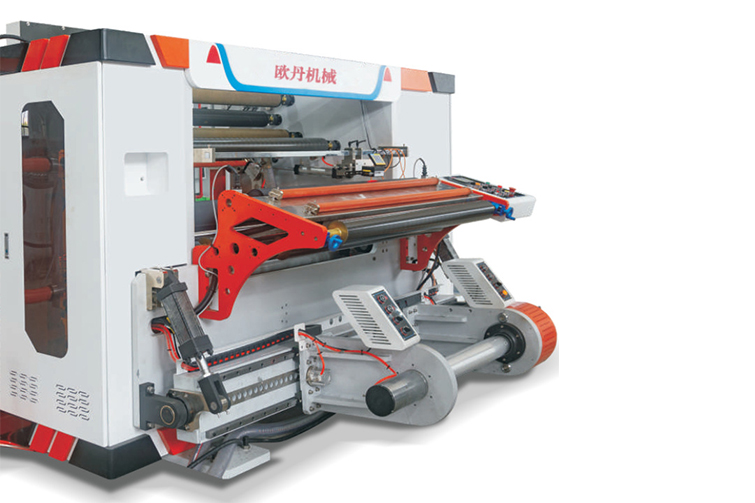

Paper slitting machines play an important role in the paper, packaging, printing, and tissue industries. They are designed to cut large rolls of paper into narrower rolls or sheets with high precision. Choosing the right machine can improve production efficiency, reduce waste, and ensure product quality. Here are the key factors to consider when selecting a paper slitting machine.

1. Define Your Application Needs

Different industries require different slitting results.

- Printing & Packaging: Requires high precision and clean edges.

- Tissue & Household Paper: Focuses more on speed and volume output.

- Specialty Paper: May require customization for thickness or coating.

Understanding your industry needs is the first step in making the right choice.

2. Machine Type and Cutting Method

Paper slitting machines can use different cutting methods:

- Razor Slitting: Suitable for thin films and lightweight paper.

- Shear Slitting: Ideal for thicker paper or materials requiring clean, accurate cuts.

- Crush Cut: Common for low-grade paper or nonwoven materials.

Selecting the right cutting method ensures both efficiency and quality.

3. Production Capacity and Speed

- Roll Width & Diameter: Ensure the machine supports the maximum roll size you work with.

- Speed: Higher speed improves efficiency but should match your production line capacity.

- Automation: Machines with automatic tension control and web guiding systems reduce manual intervention and errors.

4. Precision and Quality Control

High precision reduces waste and improves the final product.

- Look for digital control systems that provide accurate measurements.

- Check if the machine includes edge alignment systems and tension adjustment.

- Consider machines with quality inspection features for consistent output.

5. Ease of Operation and Maintenance

- User-Friendly Interface: Touch-screen panels and automated controls make operation easier.

- Maintenance Needs: Choose machines with durable blades and easy replacement parts.

- Safety Features: Emergency stop systems and protective covers are essential.

6. After-Sales Service and Support

A paper slitting machine is a long-term investment. Reliable manufacturers provide:

- Technical Training

- Regular Maintenance Services

- Spare Parts Availability

Strong after-sales support ensures minimal downtime and higher efficiency.

Conclusion

When choosing a paper slitting machine, consider your production requirements, machine type, precision level, and after-sales service. The right choice will not only improve efficiency but also reduce waste, enhance product quality, and support long-term growth. Always work with reputable suppliers to ensure reliability and durability.